The Future of Automobile Mobility Created by Fusing New Technologies

Automotive Technology Expanding with DX

This project is organized from the three perspectives of “Evolution of Cars,” “Evolution of Society and Services Surrounding Cars,” and “Evolution of Monozukuri. Evolution of the car”, ‘Evolution of society and services surrounding the car’, and ‘Evolution of manufacturing’. With the rapid acceleration of digitalization surrounding automotive technology, we hope this project will help you to think about the evolution of the automobile.

-

Evolution of Cars

Evolution of CarsCloud-Native Software Development for the Evolution of Automotive Technology

Panasonic Automotive Systems Co., Ltd.

For More Details -

Evolution of Cars

Evolution of CarsMachine Learning-Based Prediction of State of Health (SOH) for Electric Vehicle Batteries

Nissan Motor Co., Ltd. / Microsoft Research

For More Details -

Evolution of Cars

Evolution of CarsNatural Language Drive-Based 3D Model Generating Technology for Vehicle Design Assessments Accounting for Pedestrian Protection Performance

Honda Motor Co., Ltd.

For More Details -

Evolution of Society and Services Surrounding Cars

Evolution of Society and Services Surrounding CarsImmersive Audio Technology Offering Revolutionary In-Car Entertainment

Dolby Japan K. K.

For More Details -

Evolution of Cars

Evolution of CarsIn-vehicle voice interfaces evolving with location recognition AI

Mapbox Japan G.K

For More Details -

Evolution of Society and Services Surrounding Cars

Evolution of Society and Services Surrounding CarsTelematics Service Based on Automobile Insurance Combined with a Dash Cam

Tokio Marine & Nichido Fire Insurance Co., Ltd.

For More Details -

Evolution of Society and Services Surrounding Cars

Evolution of Society and Services Surrounding CarsScalable Autonomous Driving Software Platform

AISAN TECHNOLOGY CO.,LTD. / A-Drive Inc. / TIER IV, Inc.

For More Details -

Evolution of Society and Services Surrounding Cars

Evolution of Society and Services Surrounding CarsAI Congestion Forecasting: Technology That Predicts Congestion Based on Variations in Population Distribution

NTT DOCOMO, INC. / East Nippon Expressway Co., Ltd.

For More Details -

Evolution of Society and Services Surrounding Cars

Evolution of Society and Services Surrounding CarsRoad Maintenance Management Support Service

AISIN Corporation

For More Details -

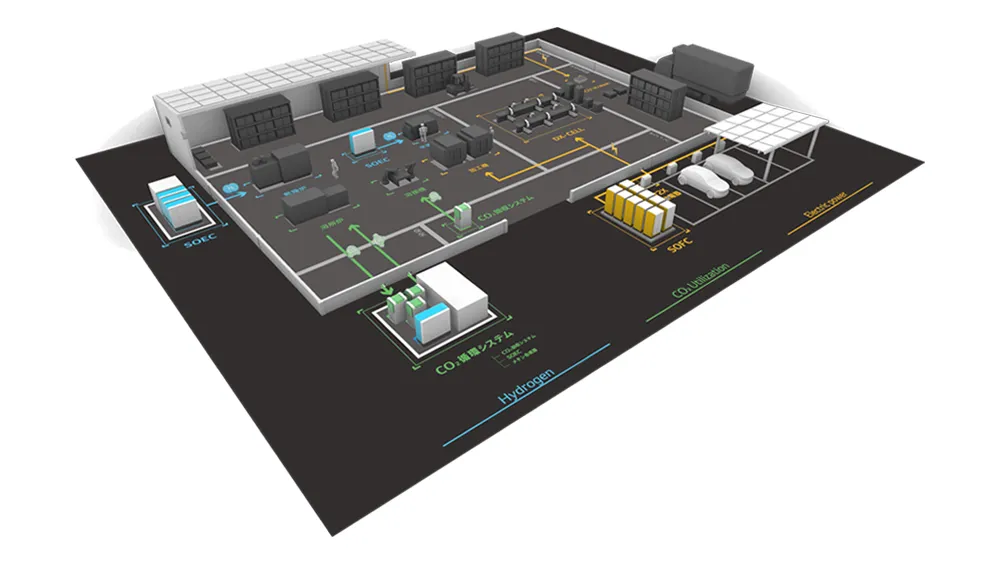

Evolution of Monozukuri

Evolution of MonozukuriShortening Machining Times Using Vibration Analysis Technology

OMRON Corporation

For More Details -

Evolution of Monozukuri

Evolution of MonozukuriBy Example Approach to Passing Down Next-Generation Technical Skill

—Technical Skill Transmission System Based on Digital Motion Analysis—Mazda Motor Corporation

For More Details -

Evolution of Monozukuri

Evolution of MonozukuriQuality Assurance Leveraging Data and AI in the Manufacturing Field

SUBARU Corporation

For More Details -

Evolution of Monozukuri

Evolution of MonozukuriOverall Optimization System for More Efficient Container Logistics Based on High Precision Position Information and Other Sensing

Toyota Motor Corporation

For More Details -

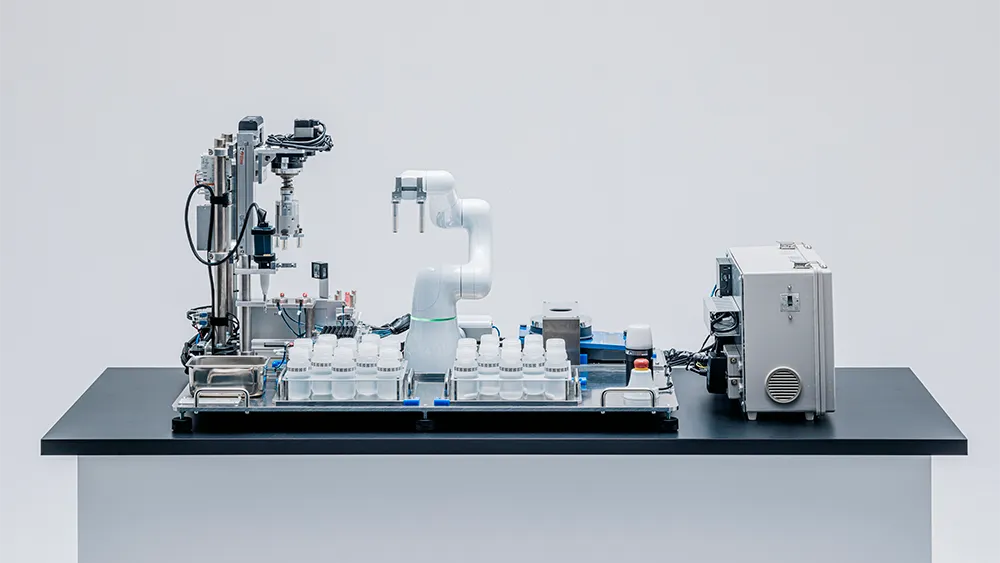

Evolution of Monozukuri

Evolution of MonozukuriLaboratory Automation Using Collaborative Robots

DENSO WAVE INCORPORATED

For More Details -

Evolution of Monozukuri

Evolution of MonozukuriDriverless Transport Solutions Using Autonomous Driving Technology

eve autonomy, Inc.

For More Details -

Evolution of Monozukuri

Evolution of MonozukuriTask Support System Drawing on Projection, Image Recognition,and Sensor Technologies

TOPPAN Inc. / AIOI·SYSTEMS CO.,LTD.

For More Details